Bringing out the engineer in you

I believe The Radical motion simulator project was a subject of interest for my of my juniors in the Singapore Polytechnic doing their FYP now. It been about 5 months since I graduated from SP as a Mechanical engineering student in Singapore polytechnic (SP), but that didn’t stop the fair bit of feedback I constantly get from my visitors, representatives from other educational institutions as well as commercial enquires from the public.

Furthermore, this project sparked interest of quite a few students researching to major in the Engineering field, and I am glad to be a mentor to this handful of prospective students considering engineering as a major (it is an interesting and fun field). It just make my day to share and light up these individual interests in the field of Engineering- making it hip and trendy to as opposed what people think of it (Engineering is not a boring field juniors!).

Personally, I never thought it to take so far off to be considered a case study by itself. This project was mainly kept secrecy at the request of my project supervisor while in development, so I never had a chance to share my experiences of the project which may prove invaluable to anyone out there looking to learn more about the project, especially for final year project students not to mention the story behind my project and the team behind it. However, since now it was featured to the public, papers and on TV during the Singapore Polytechnic Spinnovex Senior’s final year project earlier in February in this year, hey it’s no longer a secret anyone.

The simulator was featured just last month as a highlight in the Singapore Science center’s “Formula 1 Science of speed exhibition” so you might catch it there in action if you were there. So without further ago, finally got the time to actually sit down and write an entry about my final year project which was really the pride and joy for my team, the polytechnic and myself.

The radical project

This simulator was created with my team of 3 over a period of 14 weeks from scratch to finish (including testing, so technically we had like 12 weeks to build with 2 weeks to test). So without further ado, I will introduce my team members who put through the whole project thick and thin, the project will be never near what it was it it weren’t for them and their efforts.

Team Radical Members (previously known as Team Radicurl)

Lee Khowming

My course and classmate in my diploma in Engineering course. He has a technical education background in secondary school, which makes him a rather good fabricator when it comes to putting up pieces of the simulator together. On top of this engineering diploma, he is a diploma plus student who took a minor in computer programming, so that helped alot in lightening the software programming load (including the endless code debugging) where I could delegate my time to design refinement and the directional plans for the team. He is very loyal & focused to the team’s need & extremely hard- working- a very positive force to be reckoned, though sometimes you have to help point the force in the right direction at times.

Danson Han

Danson Han is the electrical guy in the team, having built and raced a mini solar car himself in this general elective modules, this guy is just one electronics guru- He can solder and fix up any electric problems as fast as a gun-slinging sheriff.

He is very much responsible of most of the electrical and lighting systems. This car crazy and racing fanatic is also our chief game analyzer and test driver who feels very much at home in school given the need to test the platform with lots of PC racing, flight and computer simulation games. This feedback were invaluable in the development and refinement of the project itself. After all, what’s better than coming to school everyday and having your job playing games everyday right?

Shaun Chng

Well I no picture needed here! My role was very much the driving force and chief engineer of the project. I was the team leader and mainly responsible of the design, concept, putting together all the design requirements and feedback from my lecturer and team on Pro-engineer CAD. I was also the one responsible for all the multimedia content as well as ensuring quality, it was a fairly hectic job which I strangely enjoyed doing. As I was fairly more experienced with designing and inventing contraptions, I have my side role there as a mentor for my teammates and teaching new things out of the book as well free-rein delegation and guiding them on their tasks if they needed any help, I picked out many new skills in soldering as well as metal work myself.

It’s a whole team effort working hand in hand and learning from each other. It’s this closely linked bond of teamwork and knowing the strengths and weakness of each of which really made this team go.

How it stated out- A car/boat you want? why not everything?

The project started out from a list of current industry need and school projects. One of the items was a force displacement motion simulator. We were allocated that as we initially highlighted to our supervisor that we wanted to build a twin seater amphibious electric Eco-racer, something like cross between a boat and a car with electric regenerative abilities- a clean energy vehicle, but we can only stick to the industry projects and that was the closest one we could see in relation to.

The build process

Planning took a rather long time, a 360 degree rotating simulator was a rather cool idea to start off- minus the possibly of simulator-induced brain trauma. The 360 simulator was something my team including myself were very excited about. But there were many restrictions our project supervisor had in place for us- especially the ones on the compact size and weight he wanted, which was puzzling as that actually added to the project complexity and cost, which we had only a mere $6000 SGD in total. Later do we know the true meaning in the later of our project what our supervisor actually meant.

Trade-offs

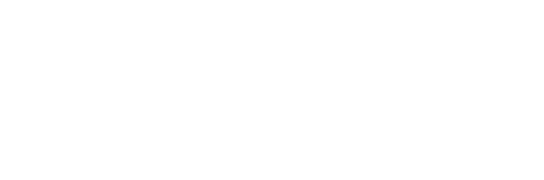

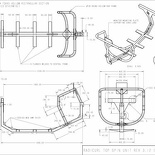

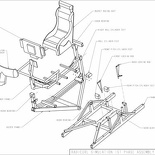

So after almost a hundred hours on the drawing board, Pro-engineer CAD, material selection, finite element (stress) analysis, rapid model prototyping and 5 major design revisions later, we settled for a 4 degree of motion cockpit mounted on 2 axis with an intermediate coupling superstructure holding the top and base together. This will give it 50 degrees of rotational freedom for both the pitch and roll axis.

We used pneumatics for mechanical actuation in place of the favorable electric linear actuators due to cost and time constraints (our calculated force requirement will require a shipment of electrical actuators from Germany taking 8 weeks), so we settled for large 63mm dia coupled to Festo pneumatic 5/3 middle closed maxi valves who had their stock in their Singapore warehouse.

How it works

Ok since you know it runs on pneumatics (air power, the same stuff which opens and closed bus doors), everything which goes on was rather straight forward, and there was no turning back. With our planned an prototype model in place to confirm all the dimension and a serious lack of time, all the mounting points and component housing were all welded and pre-made to fit the dimension specifications of the cylinders and required components even before they were delivered. Then as everything made, it’s just putting them all together like a giant plastic model piece. The dual PC setup (ethernet-networked), the 24 volt, 12 volt power supply units, as well as the central relays and power distribution unit to run peripherals such as the monitors, speakers, lighting and cooling systems. Since many of the items are custom made to fit, we saw ourselves spending quite alot of time in the workshop fabricating custom mounts and brackets to get everything all in securely in place given the forces they may encounter on a moving simulator.

You can view more on how it works, in the promotional multimedia video I’ve created for the project below:

Murphy we have a problem!

There was a brief dark moment 3 weeks before the deadline during testing where a stray current shorted the whole simulator, that caused quite a major overhaul to find the source of the short, which was later traced to a burnt IC chip in our custom built USB-pneumatic control board for the valves. The incident taught us not only much on Murphy law, but also on effective cable management (which we overlooked) and catering for troubleshooting as well.

Homerun

It’s simply great pleasure having to see all your conceptualizations, drawings and work come up to life day after day. Each day is simply just a challenge of it’s own as the deadline draws near. Simply just seeing your project rise from the nada to something which makes people go “wow” at the end of the day simply makes it all worth it- and man we were finished, on time as well! We made few minor touch-ups and refinements on top of the usual testing just before the exhibition. We even sourced a budget but authentic blue Sparco seat to finish it all up, that included an air- compressor which we loaned within campus. Thereafter was the planning phase for the exhibition booth management, so that included the creation of promotional items such as brochures, our team video, posters, setting and planning up of booth, etc. So there was always work to do. The big day finally came!

Spinnovex Exhibition!

The simulator was actually kept small and compact so that it can still be used in the confines of the exhibition area. Later do we fully understand the space requirement. The exhibition was the thing we had been looking forward to even before we started the project, the dream of showcasing out pride and joy. The exhibition was an eye opener, yet a very tense moment for me and my team given any new problems we could possibility face in the heat of the exhibition given the last shorting incident.

Moreover, it was also the first time which our simulator prototype underwent a stress test- 3 continuous days of operation for the public with riders always getting in and out (with at any one time a long queue) which was really test of the simulator built and design. Prepared for anything, we were ready with spare parts and always on standby for any problems, which unexpectedly, do occur- There was once where our compressor had condensation problems and some minor electrical problems, but we always got them all repaired on the spot with minimal downtime (most 10 minutes). The event tent power supply was rather quirky as well, as they were running on off-site diesel generators rather than the mains, so the occasional blackouts and unsteady current for all the projects at the main exhibition tent took quite an electrical beating as well. Glad ours went through without a hitch.

We’ve got some trade visitors on exhibition day, some from Japanese universities as well as some from New Zealand. It interesting to note that few university professors who came to the exhibition were surprised at the size and complexity of the project, also considering the 14 week timeline and tight budget to get it all built from scratch. Many were commenting that this project even exceed what some university students do even on their Final year project (and we were only diploma students).

Actual life video at Spinnovex

Project judging

The project judging lasted the 3 whole days of the exhibition, where judges will pop by randomly at planned random times during the day in the public and industry visitors to ask questions and a demonstration of the project. They can catch you at anytime, even during lunch. Luckily our simulator was always up and running without much downtime, so that didn’t hinder us much one bit. The press was around as well and interviewed few of the project groups as well. I was even featured in the Channel News Asia’s “Emerging Asia” programme for the project as well!

At the end of the judging round the bronze and silver awards were given out, the awards signify the tele-ed votes from all the judges over the whole exhibition duration and is award to the best project showcase. To our amazement my project came in the Gold category!

What I learned from this build

This project simply just sets a new milestone in my contribution to the polytechnic and this new engineering design course which many jokingly say “I helped build”. This engineering design course when I studied on my last year of specialization was still a rather new course, which never really saw the light with a disappointing intake my engineering design, but it was through my recommendations (e.g use of software, multimedia etc) and contributions to this new course which propelled it beyond it’s infant stages to what it is brimming with enrollment today.

I can’t deny the project is not perfect- the were few areas that were no built the way we wanted, some LEDs in the lighting system blew, the rear surround speaker don’t sit straight, even the boarding steps and wires were duct-taped instead of drilled or cable tied, but it is what that works effectively which matter. The project really made me overcome the perfectionist in me.

This project also taught me few rather new thing sin life, is that you can lose the battle to win the war. Sometimes, you have to make sacrifices in light for the good. Minor things like staying in school from 8am to 9pm every day, even coming back during public holidays and weekends just to get the project finished are just part and parcel in the darkest weeks of our project. Though our project is nothing within international standards, I am glad that we produced an engineering creation built within our own steam and ingenuity- and that is what we were proud to accomplish at the end of the day.

It simply just made the engineer in me and it will always be my passion. I am glad my project will be a continued source of motivational for anyone looking to study in the engineering field.

Hi guys,

Are you producing and selling this motion simulator ?

Thank you,

Sam

Hello Team Radical

Can we discuss further on business term relation. I’m from Malaysia and interested in your project.

I hope you will contact me to discuss further.

Yours sincerely

kmangz@gmail.com

moazam@akriz.com

Are you commercializing this simulator? I see the earlier posited comment, but do not see your reply.

how much does it cost to fabricate this simulator?

Hi all, the simulator is not for sale.

The simulator, though created by my team is a property of the polytechnic, (though the IP is somewhat retained by us). It is after all a project completely sponsored and budgeted by the school as part of my final year project.

The project is currently undertaken and further improved by my juniors, do contact the SP engineering department matter directly with regards to any further queries on commercializing the simulator.

Hi Shaun,

Could you kindly share with me the software used to create the radical simulator multimedia video for spinnovex ?

Thanks

Regards,

Yiming